#Ansys crack crack

14: A hole with a sharp notch showing crack growth.įinally, a sharp notch in the hole edge was modeled to see if the crack would be attracted. I have an Excel spreadsheet to perform this 1D approximation.įIG. The catch is that the Stress Intensity Factor range, is a function of crack length, so the equation has to be evaluated numerically. The load is dropped to a much lower level of 27.0 KN, appropriate for a continuous cyclic operational loading.Ī data probe is added to report the number of cycles for each crack increment.Ī solution for an approximate 1D solution can be found using this expression: If the stress was fully reversed, the ratio would be -1.0. In my case, the stress is cycling from zero to maximum, so the ratio is 0.0. This gives the stress range and hence the Stress Intensity factor range. The Stress Ratio is used to define the ratio of minimum stress to maximum stress. (I will be writing about non-intuitive units in a future article!) The units of the coefficient material data are tricky as they embody the exponent m in the conversion. The additional data required are the coefficient and exponent. Is the Stress Intensity Factor range (based on maximum stress and minimum stress) This requires additional material data definitions for the Paris Law. The fracture type in the SMART Crack Growth object is now set to Fatigue-an investigation of the Fracture Mechanics response under a cycling load. A crack extension limit can be defined to prevent an unrealistically long crack.

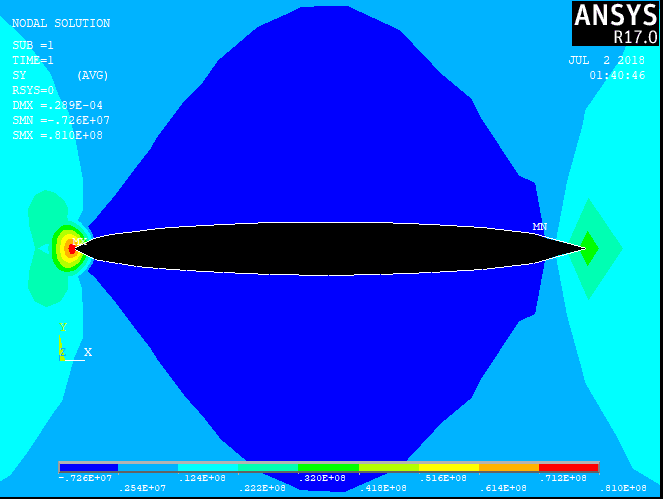

The eccentricity created by the crack would result in very large bending stresses in the residual material, as the crack runs out, with a resulting complex failure mechanism. No geometric nonlinearity allowed-so the crack length here is limited realistically unless we use a displacement control. The location to sample along the crack front can be selected, and I have used the midpoint of the crack front. 8 shows the average K I as the crack progresses, together with the threshold K c, shown as an orange dashed line. The main objective is to check the value and distribution of K I. The component will not fracture under this loading. This is below the Critical Kc of 1.5e8 input in Fig.

#Ansys crack manual

A manual calculation gives a value for KI of 6.152E7. I have constrained the bottom surface of the test piece and applied a vertical force of 1.5E5N. Each of these probes will produce an XY plot. I have also included a crack extension probe to monitor the crack growth. These values are secondary for this configuration but may become important for a crack that changes direction significantly with a resulting shear stress environment. I have also included a probe for the in-plane shearing Mode 2, which calculates K II as SIFS (K2). The probe SIFS (K1) reports these values. The main fracture mechanism in this model is the crack tensile opening Mode 1, which calculates K I. 4 shows output requests and includes general stress and displacement contours as well as fatigue-specific probes. The Failure Criteria can also be set to the J-Integral method.įig. This calculation is done along the distributed crack front, and the distribution of Stress Intensity Factor will control the adapting crack front shape. The crack will propagate when the calculated Stress Intensity Factor, K exceeds the Fracture Toughness K c. The Stress Intensity Factor method is selected in this case. The Pre-Meshed crack object is selected, the option to carry out a Static Fatigue analysis is chosen and the Critical Fracture Toughness is defined.

SMART Crack Growth is selected, and the menu is shown in Fig.

0 kommentar(er)

0 kommentar(er)